Purpose

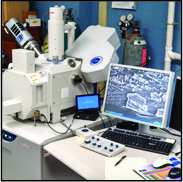

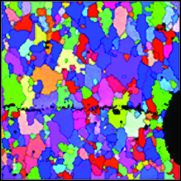

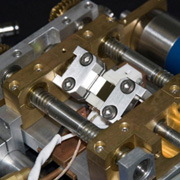

Characterize near-crack-tip damage mechanisms in metallic and metal-matrix composite materials. Perform mechanical testing within microscope chamber to allow in-situ observation of the progression of near crack tip. The lab uses SEM-based digital image correlation and other analysis tools to characterize material damage state.

Equipment/Test Method

Typical/Recent Experiments

- A Replica-based crack inspection method was developed using this equipment. Here, replicas were made of small cracks in Space Shuttle Main Engine flight hardware. Cracks as small as 100 m were able to be resolved with great reliability, representing a 15-fold improvement in the state-of-the-art crack detection method used on Space Shuttle flight hardware.

- Fatigue crack growth and fracture testing on sensory materials. Here, the nanometer-scale digital image correlation system was able to resolve displacements within shape-memory particles showing the strain required to produce a detectable phase transformation.