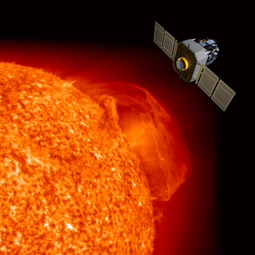

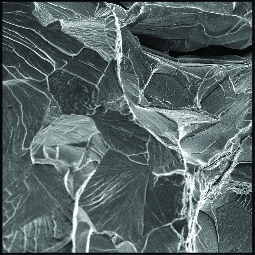

The Damage Mechanics of Metallic Materials team is performing research with focused efforts from the atomistic to continuum or component level. This work focuses on multiscale modeling and experimental interrogation of damage initiation and evolution for improved component life assessment and to inform the design of more damage tolerant materials and structures. These tools are being developed to insure safe operation of existing and emerging high performance aircraft structural designs and to enable future long duration space missions.

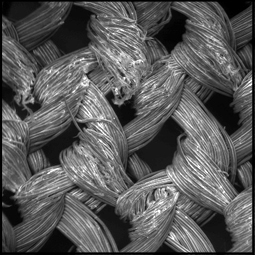

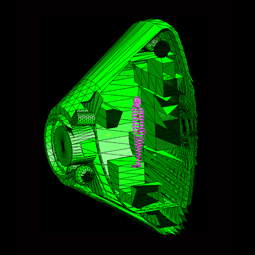

In recent years, our effort, workforce, partnerships and funded research agreements, have focused on mid-long range research in physics-based predictive tools and material design, while maintaining more traditional computational and experimental approaches. Of particular interest is the development of an improved understanding of damage processes and life prediction for materials and structures manufactured through emerging methods. Methods such as friction stir welding and additive manufacturing are enabling to the development of improved aerostructures through the reduced need for complex joints and the fabrication of highly tailored microstructures for reduced mass, reduced manufacturing costs and improved material performance. Here, these manufacturing methods enable highly tailorable and anisotropic materials, where the use of traditional continuum fracture mechanics approaches to model damage progression is insufficient.

Our team is comprised of researchers with computational and experimental expertise working in close collaboration. While the development of state-of-the-art computational and experimental methods are critical to meet our goals, it is how these tools are implemented and how the results from the computational models and experimental observations are integrated that determine our success. The Damage Mechanics of Metallic Materials discipline team has identified a set of four technical challenges that give focus to the team’s efforts to improve the state-of-the art in Damage Mechanics of Metallic Materials.

These challenges are:

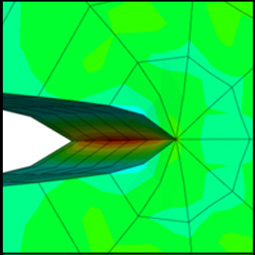

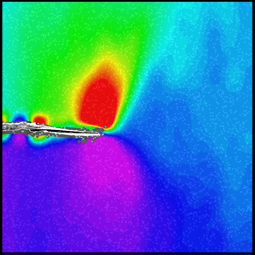

- Damage Science – Computational Approaches

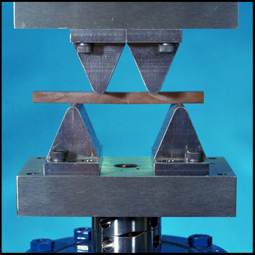

- Damage Science – Experimental Approaches

- Development of Durable Materials through Computational Design

- Continuum Modeling and Evaluation of Novel Materials Processing Methods

If you would like more information on these topics, go to the link below, which is NASA’s technical report server: http://data.nasa.gov/nasa-technical-reports-server/