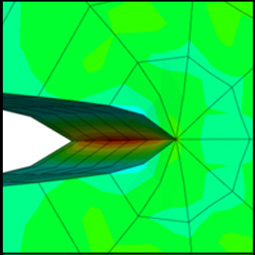

The Structural Analysis and Health Assessment (SA&HA) team within NASA Langley’s Durability, Damage Tolerance, and Reliability Branch (DDTRB) conducts innovative research in advanced structural analysis methods and structural health assessment technologies to build durable, damage tolerant, and reliable aerospace vehicles.

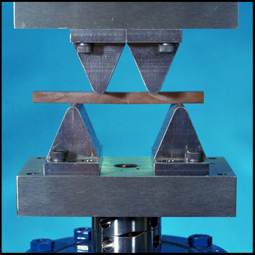

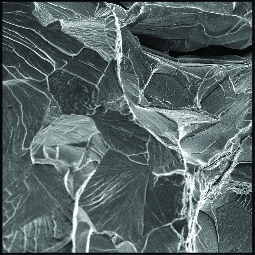

Traditional structural design methods use a deterministic approach that largely ignores the uncertainties in material properties, loading, and geometry, requiring an overly conservative design. Long-term structural safety relies on maintenance programs based on historical records of maintenance requirements, rather than continuous monitoring of structural integrity.

The structural performance and safety of aerospace vehicles can be greatly improved by incorporating advanced structural analysis methodologies and health assessment technologies into the vehicle design process. Potential benefits to vehicle designers, manufacturers, maintainers, operations, and to the public include:

- Safer vehicles that are more reliable, durable, and damage tolerant

- Lighter weight vehicles that are less costly to build

- Reduced operational costs, fuel consumption, and carbon emissions

- Increased availability by avoiding unnecessary downtime for scheduled maintenance

- Optimum use of the structure while avoiding catastrophic failures

- Minimized human involvement, thus reducing labor, downtime, and human error

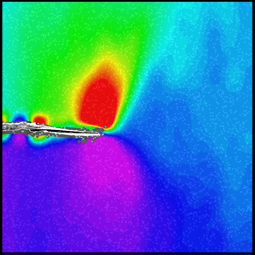

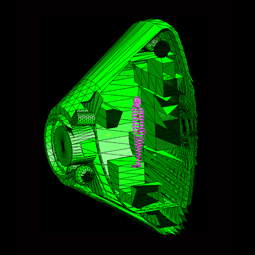

The SA&HA team has extensive experience in vehicle design, structural health monitoring, finite element methods, probabilistic methods, failure analysis, safety assessment, and tool development. Together with our governmental, commercial, military, and academic partners, the SA&HA team develops innovative tools and technologies to overcome technical challenges and achieve significant benefits through two focused research areas:

If you would like more information on these topics, go to the link below, which is NASA’s technical report server: http://data.nasa.gov/nasa-technical-reports-server/